|

|

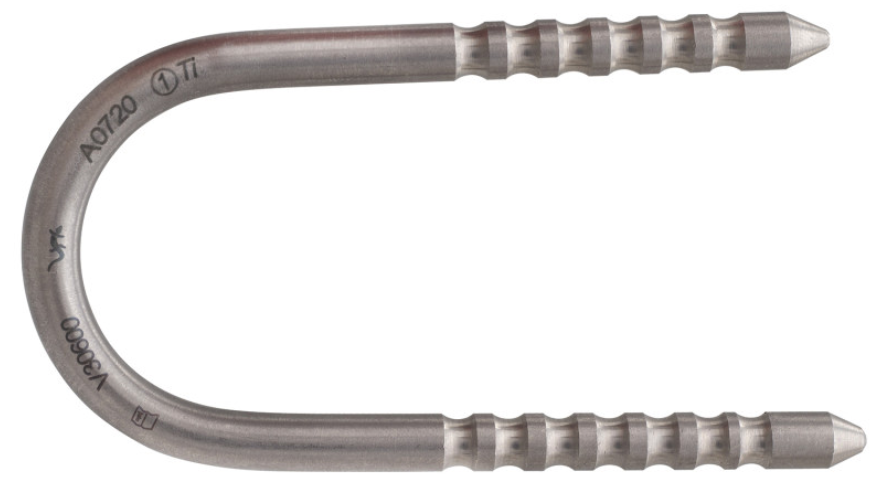

BOLT TYPES EXPANSION - RING - U-BOLT - INJECTION GLUE - RAP ANCHORS - HOW TO BOLT INTRODUCTION Before placing bolts in a cliff you must practice at home. Find a piece of portable rock or use your garage's cement foundation as a test block. Practice drilling, notching, placing and removing an example of all these types of bolts before deciding on a system. Remember - do not trust the guys in the bolt shops to tell you the right information. They have no idea about dynamic loads related to climbing and will recommend equipment that is not suitable. Bolts need to hold loads up to 25kN. Make yourself familiar with the EN959 standard for rock anchors. The Safer Cliffs reference we have prepared here will steer you towards brands that people have been using successfully for years in Australia - it is then up to you to read the technical manuals for the product and follow the instructions exactly. Contact Neil Monteith on Facebook if you need any further info. For tips on placing these bolts in a climbing environment check out the Bolting Guide. Check placing Rap Anchors as well. You should always place the fattest and longest bolt that's practical. When you're using a power drill or bolting by hand on rappel there's no excuse for placing a flimsy bolt, and at a minimum you should use a 10mm by 50mm bolt in hard rock (e.g. granite), 12mm by 75mm in medium rock (quartzite, tuff, limestone), and a 12mm by 100mm glue-in bolt in soft rock (sandstone). Bolt Types and Worldwide Best-Practice (2023 update)

|